Authors:

David Stone, Director, Virtual Construction

Michael McCaffrey, VP of safety

HITT Contracting Inc.

Technology is a huge part of day-to-day construction operations, leading to a safer, more predictable, and productive working environment. Many companies, particularly larger ones, recognize the value new tech offers in preventing injuries and thus holding off rising insurance premiums. Using technology protects their biggest asset: their employees. Their efforts to leverage technology reduce lost time for both parties while creating culture of safety within the organization.

Reducing risk through technological workflow improvements

The advent of smartphones, tablets, and Internet-of-Things (IoT)-enabled sensors allow the construction industry to leverage data that was previously inaccessible to the field worker. One such technology is 4D, which at its most basic can be described as a 3D model with the added dimension of time/schedule.

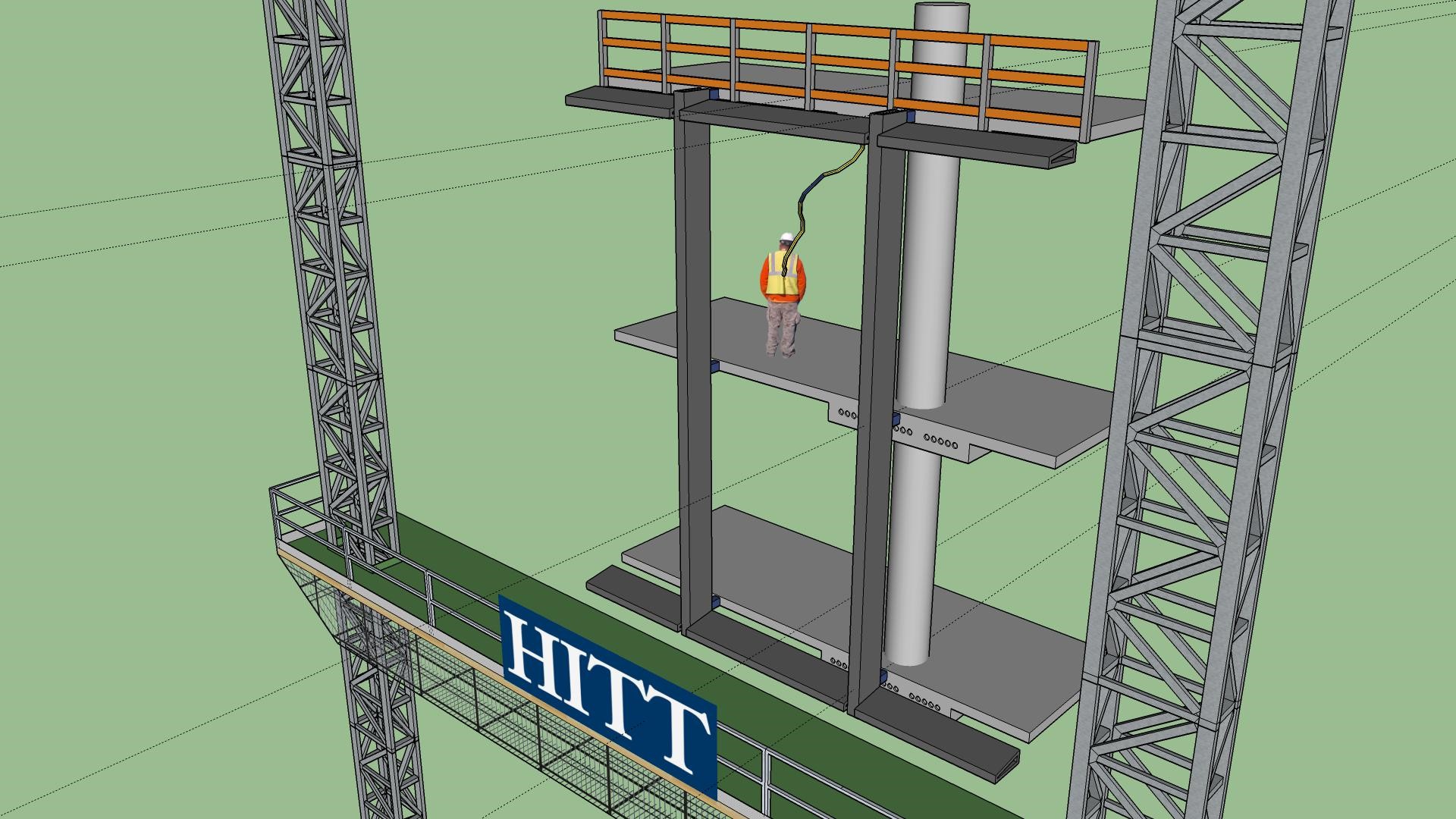

Acting as a time lapse movie of a construction site before it actually gets built, 4D can reveal issues with logistics, safety hazards, or opportunities for improvement. It is also a powerful communication tool for stakeholders, safety leads, and clients to demonstrate in simpler terms the complexity of a project. New integrated applications have allowed live models to inform the schedule and tie to the project management solution, integrating 4D with operations daily activities.

Monitoring workers activity and time on the job is another way technology aids safety. For example, the use of a badging or RFID hard-hat sticker allows superintendents and other managers to monitor the number of hours a person is on the job and how much time elapses between their shifts. This data, in turn, can be used to proactively manage risk and counsel the worker to reduce risk of injury. A more interactive method that relies on this same approach would be a wearable (e.g. smartwatches, hardhat sensors, or fitness trackers) that can measure employee vital signs and detect potential health risks such as heat stroke and hypothermia.

The combination of these new and existing technologies give field personnel and management new advantages. They are able to track progress, avoid injury from heavy equipment, and reduce injury due to improper ergonomics and fatigue. Use of computer models allow us to simulate and highlight safety elements that need to be incorporated for each phase or task, such as required equipment, clearances, or other hazards.

Virtual mockup and augmented reality provide better planning

One of the biggest challenges we have in the field is communicating the construction plan and risk in an effective way. Augmented reality provides a prime solution. By displaying the visual in a head mounted device, field workers are able to see both existing and future conditions of the construction activity.

The head mounted device is a critical distinction as it allows the worker to be free to perform work without being hampered with a handheld device, such as a smartphone or a tablet. Current devices only fill a fraction of the field of view (FoV), allowing the user to distinguish between model and real world conditions using their peripheral vision as well as other settings.

The model can then be used to inform better planning and be overlaid with safety layers of information that are pertinent to the current scope of work. In turn, safety information can be implemented and changed to match field conditions and shared instantaneously with fellow workers.

While this technology is only starting to manifest itself in construction, it is easy to see how it would allow the construction industry to increase awareness and safety using building information models (BIM). Showing hidden conditions like buried utilities, hot work permit zones, or required safety equipment in real time may significantly reduce risk while increasing the information sharing needed to perform work safely.

Preventing worker injury due to repetitive tasks or heavy lifting

Machines have been doing complex repetitive work at a high level in automotive assembly lines and other industries for decades. Used alone, these machines are not nimble enough to know how to work in a live environment with variable conditions. When connected with a human being, though, these devices function as exoskeletons, allowing the wearer to easily lift or use heavy machinery and significantly reducing fatigue and injury in field work. Initially conceived for military purposes and people with spinal injuries, this is also finding its way to construction.

Some in our industry are already benefiting from this technology, including workers who are required to hold heavy grinders or drills overhead for prolonged period of time. By augmenting the worker with an exoskeleton, the tool effectively becomes weightless.

Fatigue can reduce productivity, but more importantly it can lead to serious long term injury. This technology mitigates that risk, keeping employees safe on the job site and assisting them in their everyday tasks.

Simplifying construction through prefabrication

Prefabrication, essentially the construction industry version of the assembly line, is another area where advancements in technology have improved safety. If there are elements of the building that are repetitive at any scale (e.g. plumbing assemblies, full apartment units) they are prime candidates for being prefabricated in a controlled environment. BIM provides a level of certainty that the prefabricated elements can be assembled in the field as coordinated, while the controlled environment of prefabrication allows elimination of weather related risks. The combination improves efficiency, quality and most importantly safety.

While technology is prevalent in the construction industry, it is mostly only one step removed from the original typical consumer market use case. We see new trends emerge as advancements are adapted for our industry’s specific needs, and we are able to successfully adopting them to resolve some type of pinch point encountered on the job. As this continues, the adoption of new technologies will continue to make construction more efficient, while improving quality, and overall improving safety.

|

| Site utilities – Mixed Reality |

|

| Proximity sensors |

|

| ExoSkeleton |

|

| Vrtual Mockup – Safety installation sequence |